Piping Engineering is a specialized discipline within mechanical engineering that deals with the design, layout, analysis, and maintenance of piping systems used for transporting fluids such as liquids, gases, and slurries in various industries. These industries include oil and gas, petrochemical, chemical, power generation, pharmaceuticals, and others.

We design piping systems to meet project requirements, including material selection, pipe sizing, routing, and layout. Our Piping Engineering Team ensure that these systems are designed to safely and efficiently transport fluids while meeting regulatory requirements and industry standards.

Equipment layout

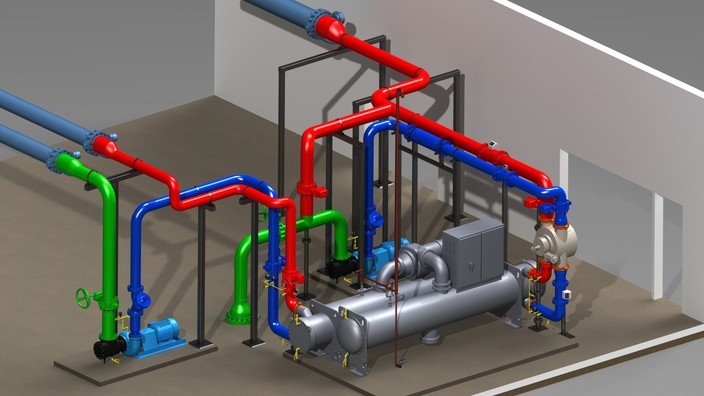

Equipment layout in piping engineering refers to the arrangement and positioning of various equipment such as pumps, compressors, heat exchangers, tanks, vessels, and reactors within a facility or plant. Proper equipment layout is crucial for ensuring efficient operation, maintenance accessibility, safety, and compliance with engineering standards and regulations.

Piping layout (GADs)

In piping engineering, General Arrangement Drawings (GADs) are detailed drawings that illustrate the layout of piping systems within a facility or plant. GADs provide a visual representation of how pipes, fittings, valves, equipment, and other components are arranged and interconnected in the overall piping network. These drawings are essential for conveying design information to stakeholders, including engineers, designers, constructors, and operators.

Isometrics for construction

Isometrics for construction in piping engineering are detailed drawings that provide a three- dimensional representation of the piping system, showing the exact arrangement of pipes, fittings, valves, and other components as they will be installed in the field. These drawings are crucial for guiding construction activities, ensuring accurate fabrication and installation of piping systems, and minimizing errors during construction.

MTO

In piping engineering, MTO stands for Material Take-Off, which is a critical process that involves quantifying and specifying the materials required for the construction of piping systems. Material Take-Offs are essential for procurement, cost estimation, project planning, and inventory management.